Industries / Companies Which May Need Centralized Filtration Systems

Our experts will always be happy to help you select proper product / combination of product for your industry application.

Swarf is generated in any type of material removing process. The swarf generated in machining is typically is of high volume and weight. Transportation of these chips from the point of generation to the scarp yard is a very tedious, time consuming and labourious job. Leaking coolant from these chips also makes the shop floor look dirty. If these chips generated are curly it adds to these problems.

Veeraja provides complete solution of swarf removal from machine bed , common conveying systems, chip crushers and chip briquetting machines.

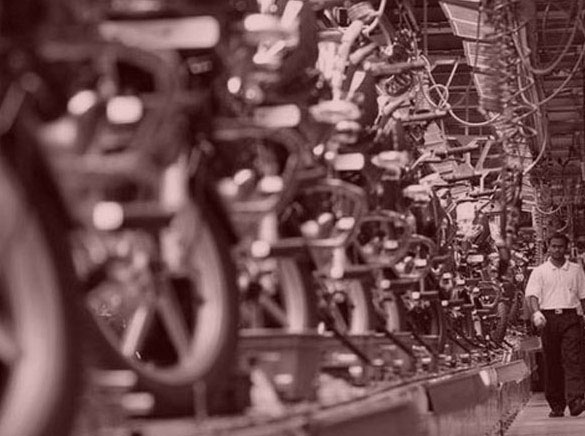

A world class manufacturer in India. They manufacture 2 wheelers and 3 wheelers wide range of products.

A world class manufacturer in India. They manufacture 2 wheelers and 3 wheelers wide range of products.

Application : Aluminum machining

Process : Machining, Drilling, Tapping, Boring

No of machine : 80 No’s

Fluid : Water based emulsion

Multiple part of a 2 wheeler are made of aluminum die cast. Components are machines, drilled and bored to achieve finished stage. This generates large quantum of chips. Considering the high production requirements multiple machines are working at the same time.

This generates a large quantum of chips. Chips were separated in individual tanks and fluid pumped back to machine. Chips had to be cleaned manually from each tank. This caused significant machine downtime. Customer wanted to reduce this machine down time and if possible completely eliminate it.

Properties of coolant like pH, concentration etc. had to be maintained at each machine. This caused irregularities and required lot of manpower. Due to the space limitation available for individual tanks, filtration level achieved was compromised resulting improper filtration reducing the coolant life and frequent breakdown of machines.

Customer wanted to explore the possibility of adding additional machine in the same shop floor to match the ever increasing production demand

Veeraja proposed a centralized filtration system with large conveyors and mesh drum filters. A layout was prepared with the process planners from Bajaj Auto ltd. Civil trenches were dug in existing machine shop. Advance in civil engineering has made it possible to dig inside the shop floor without disturbing adjacent machines.

Careful coordination with various agencies and technical team Bajaj Auto Ltd ensured that production is hampered the least. A large pit to accommodate a 15000 LPM central filtration which total tank capacity of more than 1,00,000 liters was constructed outside the shop. U shape gutters were fitted in the trenches and a central filtration was installed in the pit. A regularly tracked project execution ensured on time delivery and smooth transition from individual to Centralized filtration system

Individual tanks were removed and dirty fluid outlets of all machines were connected to the U shaped gutters. These carry the fluid and chips to the CFS. Sufficient gradient ensured all is transferred without any blockage and accumulation. Additional flushing nozzles tapped from high pressure supply line are used at regular intervals.

A world class manufacturer in India. They manufacture 2 wheelers and 3 wheelers wide range of products.

Application : Aluminum machining

Process : Machining, Drilling, Tapping, Boring

No of machine : 80 No’s

Fluid : Water based emulsion

Multiple part of a 2 wheeler are made of aluminum die cast. Components are machines, drilled and bored to achieve finished stage. This generates large quantum of chips. Considering the high production requirements multiple machines are working at the same time.

This generates a large quantum of chips. Chips were separated in individual tanks and fluid pumped back to machine. Chips had to be cleaned manually from each tank. This caused significant machine downtime. Customer wanted to reduce this machine down time and if possible completely eliminate it.

Properties of coolant like pH, concentration etc. had to be maintained at each machine. This caused irregularities and required lot of manpower. Due to the space limitation available for individual tanks, filtration level achieved was compromised resulting improper filtration reducing the coolant life and frequent breakdown of machines.

Customer wanted to explore the possibility of adding additional machine in the same shop floor to match the ever increasing production demand

Veeraja proposed a centralized filtration system with large conveyors and mesh drum filters. A layout was prepared with the process planners from Bajaj Auto ltd. Civil trenches were dug in existing machine shop. Advance in civil engineering has made it possible to dig inside the shop floor without disturbing adjacent machines.

Careful coordination with various agencies and technical team Bajaj Auto Ltd ensured that production is hampered the least. A large pit to accommodate a 15000 LPM central filtration which total tank capacity of more than 1,00,000 liters was constructed outside the shop. U shape gutters were fitted in the trenches and a central filtration was installed in the pit. A regularly tracked project execution ensured on time delivery and smooth transition from individual to Centralized filtration system

Individual tanks were removed and dirty fluid outlets of all machines were connected to the U shaped gutters. These carry the fluid and chips to the CFS. Sufficient gradient ensured all is transferred without any blockage and accumulation. Additional flushing nozzles tapped from high pressure supply line are used at regular intervals.

Client Speak

Client Speak

78/1, Shantiban Industrial Estate,

Shivane, Pune - 411023.

Maharashtra, India.

Centralized Filtration Systems: +91 7350771200 Skimmers & Magnetic Separators: +91 7350771300 Others : +91 9922931696

For any query regarding Products or solutions, write to our engineers

CFS for Aluminium Machining CFS for Steel Machining CFS for Cast Iron Machining Grinding Honing Swarf Handling Systems