A Centralized Filtration System is basically a Common Filtration System for a group of machines. Hence a centralised filtration can cater to a small group of machines or the complete shop. It is generally a combination of various Coolant Filtration System Products and Accessories.

A Centralized Filtration System is the most effective and efficient ideology in Coolant Filtration System and Cutting Oil Filtration System.

A Centralized Filtration System has huge benefits over a Individual Filtration System.

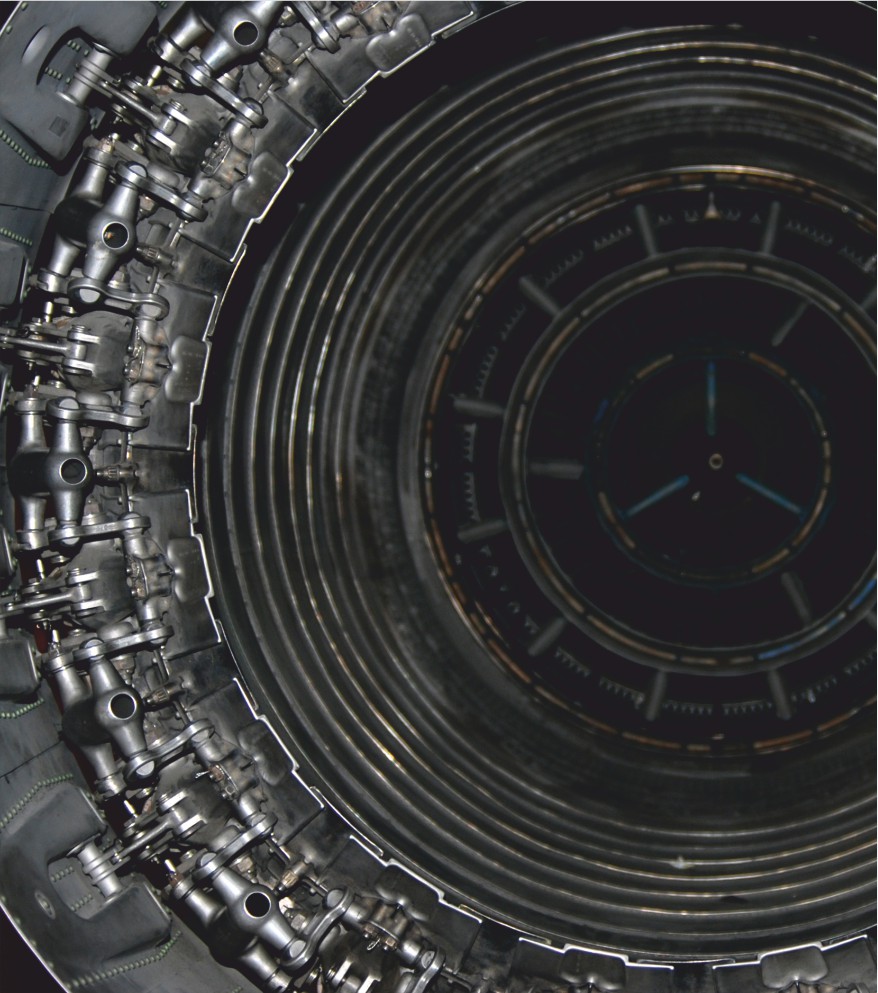

In a CFS the dirty fluid from the machines has to transfer to the system. The image shown is of CFS for Cast Iron machining with underground gutter.

Underground Gutter

U shaped gutters are placed along the machine below the shop floor level. Dirty fluid from the machine drops in these gutters. These gutters are inclined to give a gradient towards the centralized filtration system. Inclination is calculated based on the dirt coming from the machine.

A. Grids of civil trenches are made inside the shop floor.

B. Metallic U shaped gutter are placed inside these trenches.

C. Dirty fluid from machines drops into these gutters instead of those messy tanks. These gutters placed in such a way that the fluid along with the chips flows towards the CFS.

D. Enough slope is provided to the gutters to facilitate the flow of coolant along with the chips. Both these metallic gutter and the civil trenches have covers that means all the dirty fluid is below the shop floor away from eye contact but can be accessed easily.

E. ThisThis grid of gutter joins into a main gutter which in turn connects to the CFS.

F. The CFS is placed in a pit where the filtration system, clean tanks and pumps are placed. This is where it is filtered to the required quality.

G. The pumps supply the fluid through pipes which are laid next to the gutters inside the trenches.

If underground gutter construction is not possible, dirty fluid transfer can be done in another way

Tanks with pumps and electrical control panel are placed near machines. Dirty fluid from machine drops in these tanks. The pumps transfer the dirty fluid into overhead dirty fluid return piping. The pump is tuned ON/OFF with help of the panel.

Dirty fluid from transfertank is pumped into overhead pipes. The piping is sized and positioned to facilitate the easy flow of dirty fluid. Pulse Jet system can be used to reduce the piping size by generating the required flowvelocity..

In a

Centralized

Filtration System the dirty fluid from the machines has to transfer to the

system. The

transfer can done in various ways:

In a

Centralized

Filtration System various instrumentation and electronic systems are used to

further

increase the effeciency and make it user friendly. Some of these facilities

alongwith

its benefits are listed below:

Gearbox Cover Drilling |

Pressure Die

Cast

Component Machining | Gravitaon Die

Cast Machining

Break Drum | Cranksha |

Cylinder Head

Cylinder Lock | Camsha | Breakliner

Water Pump Shas Grinding

Diesel Injecon Nozzle | Cylinder Liner Honing

Camsha Grinding | Cranksha Grinding

Ball Bearing | Taper Roller Bearing

Piston Rod Grinding | Cylindrical Bearing

Bearing Inner & Outer Race

Chip Cuer | Magnec

Separators

Conveyors | Scraper Conveyors

Screw Conveyors | Candle Type Separators

Drum Type Separators

Self-cleaning Filters

Flow - 15000 LPM, Connected M/c - 100, 2 Wheeler

Flow - 1000 LPM, Connected M/c - 7

Flow - 7500 LPM, Connected M/c - 50

Flow - 20000 LPM, Connected M/c - 134

Flow - 10000 LPM, Connected M/c - 67

Flow - 4000 LPM, Connected M/c - 27

Flow - 6000 LPM, Connected M/c - 40

Flow - 10000 LPM, Connected M/c - 50

Flow - 15000 LPM, Connected M/c - 100, 3 Wheeler

Flow - 15000 LPM, Connected M/c - 100, 3 Wheeler

Flow - 6000 LPM, Connected M/c - 40

Flow - 5000 LPM, Connected M/c - 30

Flow - 10000 LPM, Connected M/c - 67

Flow - 10000 LPM, Connected M/c - 67

Flow - 10000 LPM, Connected M/c - 67

Flow - 6000 LPM, Connected M/c - 40

Flow - 8000 LPM, Connected M/c - 53

Flow - 8000 LPM, Connected M/c - 53

Flow - 3000 LPM, Connected M/c - 20

Flow - 8000 LPM, Connected M/c - 53

Flow - 8000 LPM, Connected M/c - 53

Flow - 8000 LPM, Connected M/c - 53

Flow - 8000 LPM, Connected M/c - 53

Flow - 8000 LPM, Connected M/c - 53

Cylinder liner honing

Surface Grinding

Injector Nozzle

Hydraulic Cylinder

Hydraulic Cylinder

Hydraulic Cylinder

Water Pump Grinding

Engine Valve Grinding

Steering Rod Grinding

Compressor Grinding

Compressor Grinding

Compressor Grinding

How CFS Helps At Different Levels In Your Organization?

Save 25% Shop Floor Utilisation & Increase Production By 25%

How CFS Will Help Reduce Machine Maintenance & Manpower Costs?

Centralized Filtration System For Long Term Benefits & Increased ROI

How Production Managers Can Achieve Production Targets With No Machine Breakdown?

How Veeraja's Centralised Filtration System Technologies Help Purchase Manager?

78/1, Shantiban Industrial Estate,

Shivane, Pune - 411023.

Maharashtra, India.

For any query regarding Products or solutions, write to our engineers

For Supplier Inquiries: Suppliers interested in collaborating with us can reach out:

Auto OEM

Auto Component

Manufacturers

Bearing Industry

Steel Rolling Mills Manufacturers

Steel Rolling Mills

Machine Tool Manufacturers

CFS for Aluminium Machining CFS for Steel Machining CFS for Cast Iron Machining Grinding Honing Swarf Handling Systems