Industries / Companies Which May Need Centralized Filtration Systems

Our experts will always be happy to help you select proper product / combination of product for your industry application.

Grinding process is used to generate better surface finish on components. Alongwith the removal of metal particle, the grinding wheel is also consumed. If proper filtration is not provided these particles escape the filtration system and generate scratch marks on the surface deteriorating the Ra and Rz values. The particles also clog the grinding wheel, which needs to re-dressed frequently. This increases the consumption of the grinding wheel.

A CFS for Grinding process is sized based on wheel grit size, viscosity of fluid and material of component. As the viscosity increases or the grit size becomes finer, the flow velocity through filter media has to be reduced to achieve desired results.

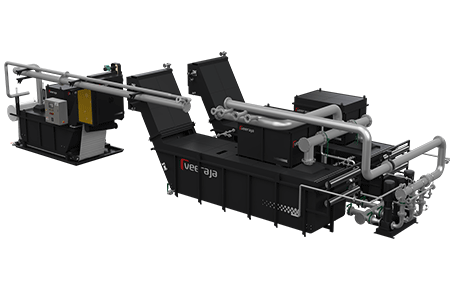

A CFS for grinding is similar to indivisual filtration system but at a much larger scale. Dirty fluid alongwith grinding muck falls into the vacuum filter. Dirt cake is generated on the filter media ( check the actual working ). Clean fluid is directly pumped back to the machines.

Our experts will always be happy to help you select proper product / combination of product for your industry application.

78/1, Shantiban Industrial Estate,

Shivane, Pune - 411023.

Maharashtra, India.

For any query regarding Products or solutions, write to our engineers

For Supplier Inquiries: Suppliers interested in collaborating with us can reach out:

Auto OEM

Auto Component

Manufacturers

Bearing Industry

Steel Rolling Mills Manufacturers

Steel Rolling Mills

Machine Tool Manufacturers

CFS for Aluminium Machining CFS for Steel Machining CFS for Cast Iron Machining Grinding Honing Swarf Handling Systems