For precision processes like grinding and honing, achieving a finer filtration level is crucial. If the fluid is not filtered to the desired level, residual particles can cause unwanted marks on the surface, compromising quality. Traditional gravity filters often fall short, offering insufficient filtration and leading to high media consumption.

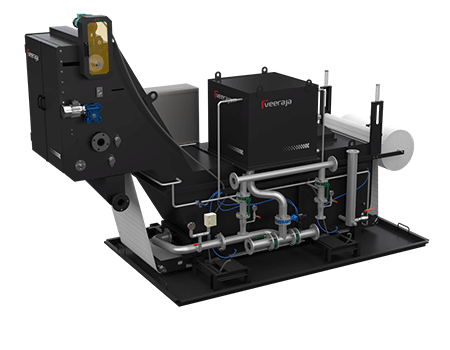

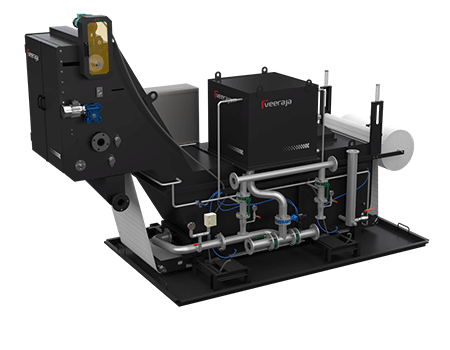

In such scenarios, Vacuum Filters emerge as the perfect solution. By leveraging vacuum technology, these filters can utilize finer filter media, making them ideal for ultra-fine filtration requirements. When space is a constraint, our Compact Vacuum Filter provides an efficient solution. It combines the advantages of a vacuum filter with a minimal floor space requirement, ensuring excellent performance even in space-restricted environments.

78/1, Shantiban Industrial Estate,

Shivane, Pune - 411023.

Maharashtra, India.

For any query regarding Products or solutions, write to our engineers

For Supplier Inquiries: Suppliers interested in collaborating with us can reach out:

Auto OEM

Auto Component

Manufacturers

Bearing Industry

Steel Rolling Mills Manufacturers

Steel Rolling Mills

Machine Tool Manufacturers

CFS for Aluminium Machining CFS for Steel Machining CFS for Cast Iron Machining Grinding Honing Swarf Handling Systems