Industries / Companies Which May Need Centralized Filtration Systems

Our experts will always be happy to help you select proper product / combination of product for your industry application.

Galvanising line filtration system has many functions. It has to remove the scale and scum generated during rolling. The temperature has to be controlled along with flow and pressure.

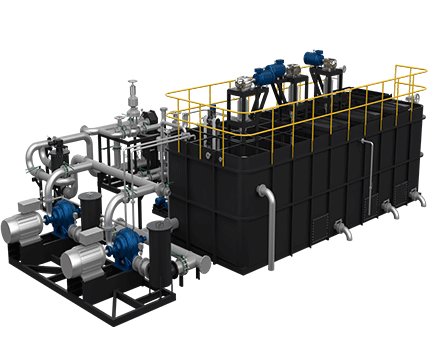

A Galvanising line system usually consists of a large tank. The dirty fluid enters into the dirty fluid compartment. Using baffles the complete flow is passed through Magnetic separator into the semi clean compartment. This fluid is then sucked by large pumps and passed through self-cleaning filter and PHE skid to control the temperature. A pressure control valve ensures constant pressure is supplied to the mill.

The tanks have agitators to continuously mix the coolant. Belt skimmers are also mounted on the tank to remove the floating scum. To maintain the temperature of the tank, either electrical heaters are placed in thermic fluid tubes or the coolant is passed through housing heated by electrical heaters or steam. If finer filtration required then a different set of pumps are used to transfer dirty fluid to pneumatic vacuum filters.

Our experts will always be happy to help you select proper product / combination of product for your industry application.

78/1, Shantiban Industrial Estate,

Shivane, Pune - 411023.

Maharashtra, India.

For any query regarding Products or solutions, write to our engineers

For Supplier Inquiries: Suppliers interested in collaborating with us can reach out:

Auto OEM

Auto Component

Manufacturers

Bearing Industry

Steel Rolling Mills Manufacturers

Steel Rolling Mills

Machine Tool Manufacturers

CFS for Aluminium Machining CFS for Steel Machining CFS for Cast Iron Machining Grinding Honing Swarf Handling Systems