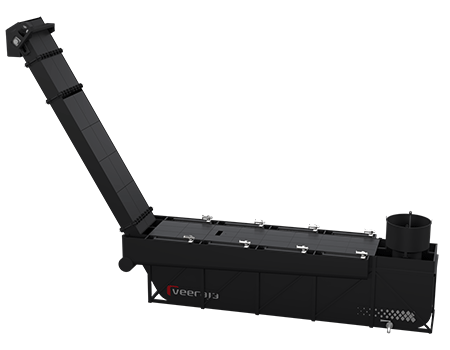

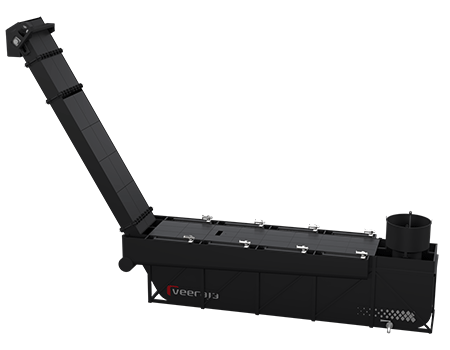

Scraper Conveyer is a simplest device to handle course dirt in bulk. It can be designed in several forms: inserted in a machine tunnel or placed at the bottom of dirty fluid holding tank. It also can be used in combination with a verity of filtration / separation devices.

Wipers are attached to a moving chain placed in trough (tank) holding dirty cutting fluid. Sediment course dirt is moved along with the wipers in a bin placed at one end of trough.

The sketch shows two basic types of conveyers. Type A is normally used in machine tools, in combination with a magnetic separator (optional) to handle finer magnetic dirt. Type B shows a scraper conveyer placed at dirty fluid holding tank, in combination with Up-flow drum filters (optional) to handle large quantity of non-magnetic dirt.

78/1, Shantiban Industrial Estate,

Shivane, Pune - 411023.

Maharashtra, India.

For any query regarding Products or solutions, write to our engineers

For Supplier Inquiries: Suppliers interested in collaborating with us can reach out:

Auto OEM

Auto Component

Manufacturers

Bearing Industry

Steel Rolling Mills Manufacturers

Steel Rolling Mills

Machine Tool Manufacturers

CFS for Aluminium Machining CFS for Steel Machining CFS for Cast Iron Machining Grinding Honing Swarf Handling Systems